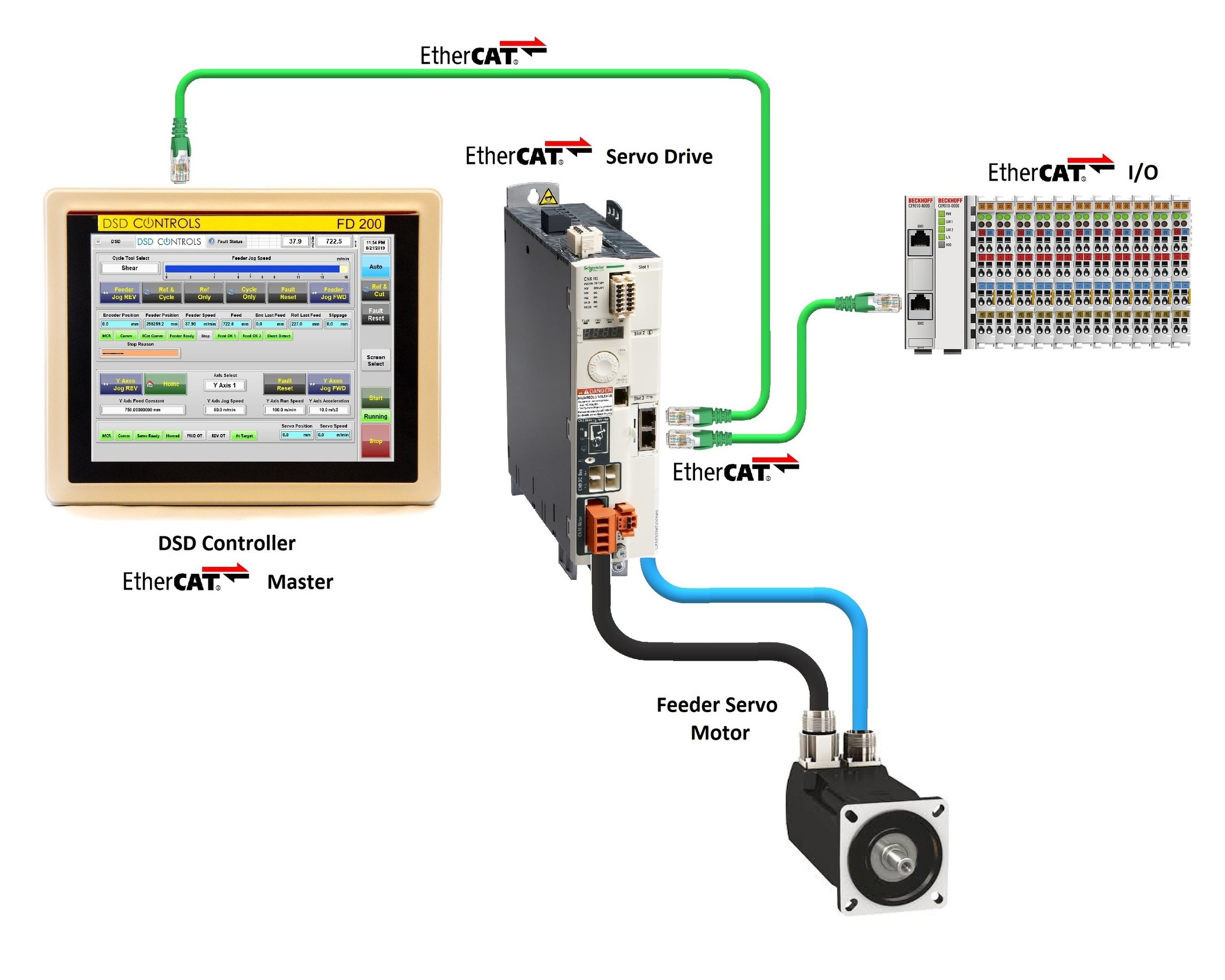

FD200 Servo Feeder Controller

We designed the FD200 controller to be an ultimate controller for the servo feed machines. Beside the main servo feeder, this controller can handle multiple Y-axes Servo Driven punch presses. It can have as much as 128 presses and or gags. It has a built in production data logger which is accessible to the operator and will keep track of all the machine production and events. following is a brief description of the controller and its capabilities:

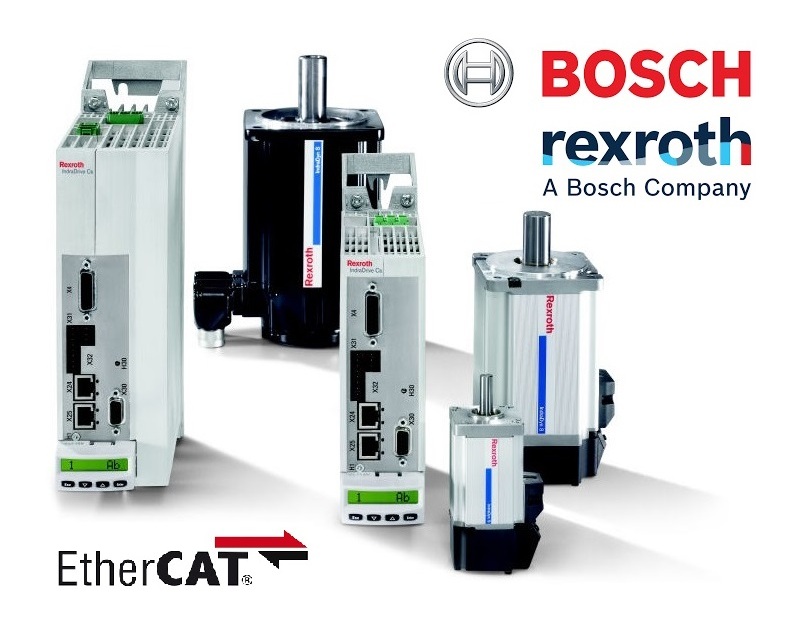

Works with most servo drives such as Bosch-Rexroth, ABB, Schneider, Omron, Parker, Panasonic, Yaskawa …

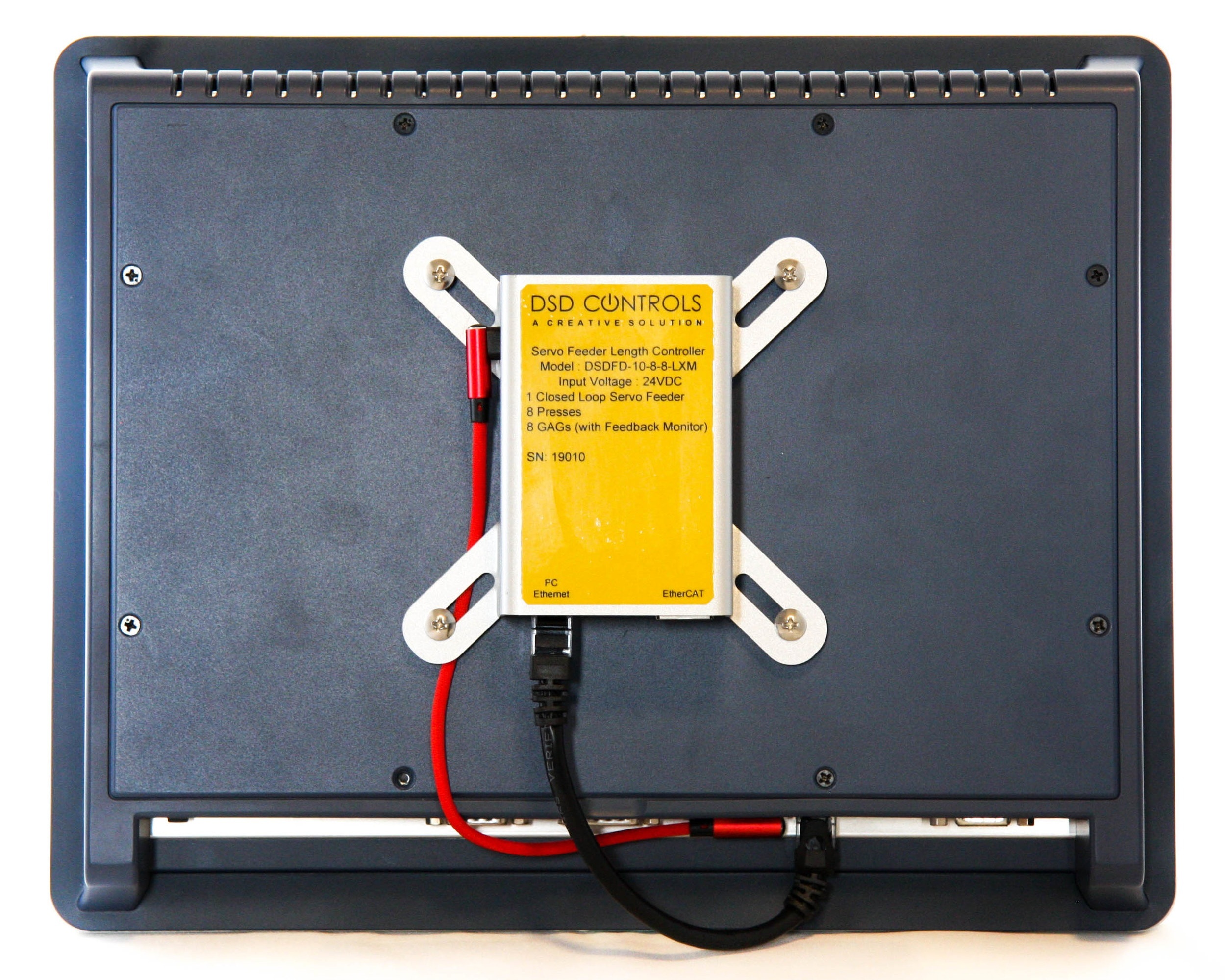

Large industrial IP65 panel computer with resistive touch screen, all solid state and no moving part

The standard sizes are 12” and 15” (Other sizes such as 17”, 19” and larger are available as special order)

Multiple password and access level for operators, supervisor, engineer, designer and administrator

Back-up and Restore all the settings, tool programs, passwords and part programs on local hard drive or on a USB memory stick

Metric & fractional Imperial dimension system

Multiple Y-Axes

Multiple presses and gags (up to 128 presses and or gags)

Integrated GAG feedback monitor

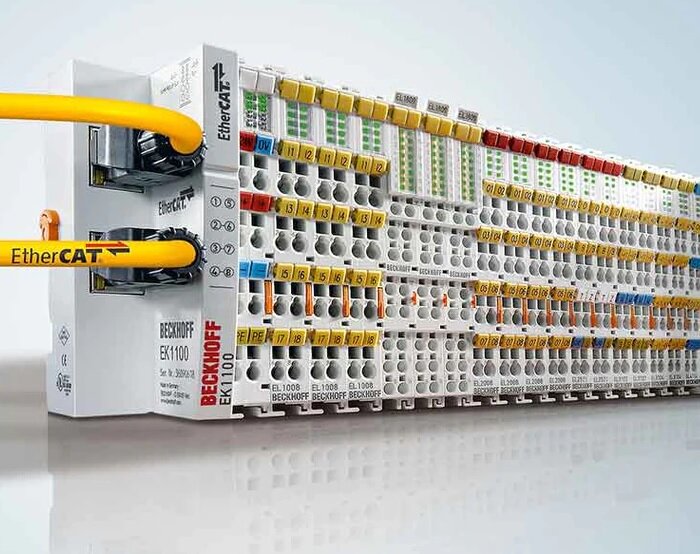

Remote I/O over EtherCAT, no need to bring any wire to the controller, only an Ethernet cable

Configurable I/O based on application

Integrated event and production log, the logger keeps track of all the events and production data

(Optional) Wireless Jog Push Button

(Optional) Line encoder to detect the material slippage for safety or slippage compensation

(Optional) Database connectivity to connect to any standard database such as SQL server to receive production recipe and send the production report

(Optional) CAD file to part program conversion

(Optional) Remote access over Internet. By providing an Internet connection to the controller, our technician can connect to the controller anywhere in the world to monitor, configure, upgrade or troubleshoot

This controller is suitable for following applications:

Purlin lines

HVAC lines

Any servo feed application